- Anchor Chain

- Marine Anchor

- AC-14 HHP Anchor

- CJ-14SB HHP Anchor

- Danforth HHP Anchor

- Delta HHP Anchor

- CJT-20 HHP Anchor

- MK5 Anchor

- Matrosov Anchor

- D-HONG HHP Anchor

- Pool HHP Anchor Type N

- CJN-SB Type HHP Anchor

- GB 11579-89 Light Weight Anchor

- Spek Anchor

- Typeb A.B.C Hall Anchor

- Japan Stockless Anchor

- Japan Stock Anchor

- U.S.N Stockless Anchor

- Beldt Stockless Anchor

- Admiralty Anchor

- Single Fiuke Anchor

- Stainless Steel Anchor

- Marine Outfitting Equipment

- Marine Buoys

- Marine Equipment

Pneumatic Rubber Fender

Andy Marine is a large heavy industry enterprise specializing in the research and production of Pneumatic Rubber Fender. Pneumatic rubber fender is made of synthetic-cord-reinforced rubber sheet with compressed air inside to enable it to float on the water and work as a shock absorber between two ships, or between ships and berthing structures when they come alongside each other on the water.

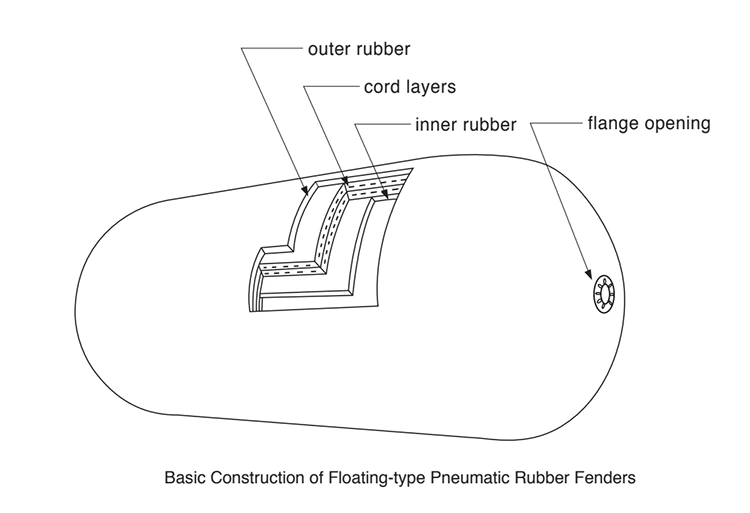

The pneumatic rubber fender body is constructed of an inner rubber layer, reinforced cord layers and an outer rubber layer. All of these layers are vulcanized together. The outer skin rubber compound is designed and manufactured to be able to withstand both strenuous use including abrasion during adverse weather conditions whilst protecting the cord layers and inner rubber. The synthetic tyre cord layers are arranged and designed to distribute load and stress evenly, which maintains the internal air pressure of the fender. The inner rubber compound is designed to be completely airtight, utilising a compound equivalent to that an inner tube of a car tyre.

Send Inquiry

Pneumatic rubber fender is a leading anti-collision device for marine applications in the world today. This fender is made of synthetic-cord-reinforced rubber sheets with compressed air inside to enable it to float on the water and work as a protective medium.Therefore ,pneumatic rubber fenders serves as a critical protective medium against collision when ship-to-ship (STS) transfer operations and ship-to-dock (STD) berthing and mooring operations.

Pneumatic rubber fenders have the advantages of massive energy absorption with low unit surf-ace pressure act upon the ship.So pneumatic rubber fender has become an ideal ship protection medium used extensively by large tankers,LPG vessels, ocean platforms,bulk carriers and floating structures,large docks,harbor and wharfs.

Construction Features

Floating pneumatic rubber fenders, whose basic body construction coinssts of outer rubber layers, synthetic-cord-reinforced rubber layers and inner rubber layers, are kind of cylindrical air bags with hemispherical heads at both ends.

Outer Rubber: The outer rubber layer that covers the outside of fender protects the cord layers and the inner rubber form abrasion and other external forces. This compound has sufficient tensile and tear strength to withstand any weather condition and hard usage. Standard color is black, but other colors such as grey and creamy white are available on request.

Inner Rubber: The liner of a rubber membrane seals the pressurized air inside the fenders.

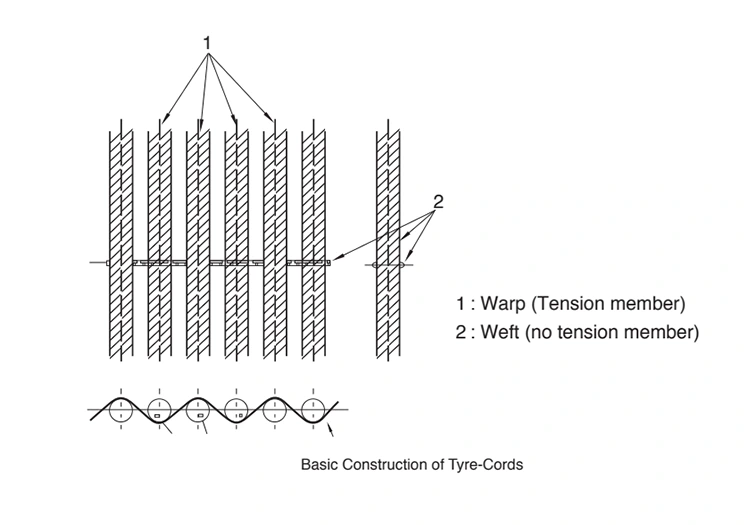

Cord Layers: The reinforcement cord layers,which are made of Synthetic-tire-cord commonly used in tires,are arranged at ideal angles to hold the internal pressure to provide strong efficient reinforcement and distribute the stress evenly.

Safety Valve: On the large size fenders,the safety valve is equipped for releasing excess internal pressure when the fender is accidentally over compressed.

Flange Opening: A steel flange to which an air valve or safety valve can be adapted is mounted on the fender.

Metal Accessories: All the relevant metal accessories of pneumatic fenders, including shackles,towing rings,swivels,chain net,are made of stainless steel, and Hot Dipped Galvanized (HDG),which is resistant for seawater corrosion.

Pneumatic Rubber Fender Types

Initial Internal Pressure Rating

There are two initial pressure rating for Andy Marine Pneumatic Rubber Fenders:

A) Pneumatic 50 (Initial internal pressure 50kPa)

B) Pneumatic 80 (Initial internal pressure 80kPa)

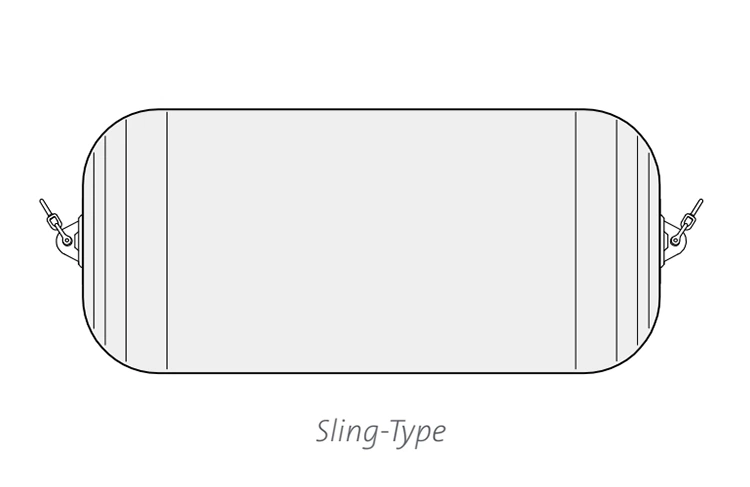

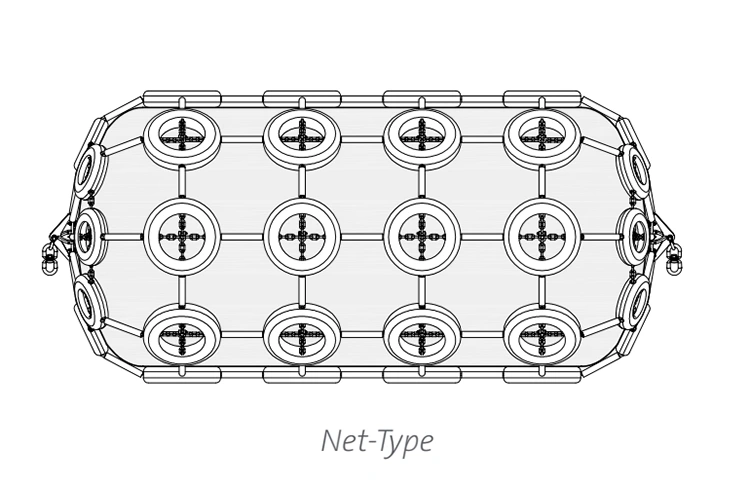

There are two types for Andy Marine Pneumatic Rubber Fenders:

1)Type Ⅰ- Sling-type Fender

The fender is designed to be used without a protection net. lt's easy to handle because of their light weight.

2)Type Ⅱ - Net-type Fender

The fender is covered by a protection net consisting of chain , and usually with tires or rubber sleeves.

Because of the multiformity of applications, Andy Marine can adjust his designs to meet the clients various requirements, such as net variations, different colors and various end fittings.

Pneumatic Rubber Fender Advantages

• Compliance with lSO17357:2002

• More Safety and Reliability

• Lower Mooring Forces

• Adaptable to the Tide

• Low Maintenance Cost

• Low Reaction Force and Hull Pressure

• Most Cost Competitive System

• Advantage against Shearing Force

• Simple and Low Cost installation

• Various Optional Fitting

Pneumatic Rubber Fender Size

|

Specification |

Initial internal pressure P0=50kpa (0.5kgf/cm2) |

Initial internal pressure P0=80kpa (0.8kgf/cm2) |

||||

|

Dia*Length (mm) |

Weight of Sphere(kg) |

Reaction Force (KN) |

Guaranteed Energy (KJ) |

Weight of Sphere(kg) |

Reaction Force (KN) |

Guaranteed Energy (KJ) |

|

500*1000 |

25 |

64 |

6 |

25 |

85 |

8 |

|

600*1200 |

32 |

86 |

10 |

32 |

108 |

13 |

|

700*1500 |

50 |

137 |

17 |

50 |

180 |

24 |

|

1000*1500 |

80 |

182 |

32 |

80 |

239 |

45 |

|

1000*2000 |

100 |

257 |

45 |

125 |

338 |

63 |

|

1200*2000 |

120 |

297 |

63 |

165 |

390 |

88 |

|

1350*2500 |

165 |

427 |

102 |

226 |

561 |

142 |

|

1500*3000 |

315 |

579 |

153 |

370 |

761 |

214 |

|

1700*3000 |

405 |

639 |

191 |

436 |

840 |

287 |

|

2000*3500 |

590 |

875 |

308 |

632 |

1150 |

430 |

|

2500*4000 |

1050 |

1381 |

663 |

1110 |

1815 |

925 |

|

2500*5500 |

1333 |

2019 |

943 |

1410 |

2653 |

1317 |

|

3000*5000 |

1880 |

2000 |

1050 |

2155 |

2709 |

1571 |

|

3000*6000 |

2160 |

2488 |

1312 |

2470 |

3292 |

1888 |

|

3300*4500 |

2020 |

1884 |

1175 |

2300 |

2476 |

1640 |

|

3300*6000 |

2300 |

2783 |

1675 |

2600 |

3652 |

2338 |

|

3300*6500 |

2700 |

3015 |

1814 |

3080 |

3961 |

2532 |

|

3300*10600 |

4403 |

5257 |

3067 |

5020 |

6907 |

4281 |

|

4500*9000 |

6554 |

5747 |

4752 |

7470 |

7551 |

6633 |

Notice Of Pneumatic Rubber Fender Application And Storage

1.The pneumatic rubber fender pressure should be kept in the standard pressure, within the rate of ±5% range.

2.Often check the pressure, when the pressure drops, Inflate the fender in time, so as not to affect the normal use of the fender.

3.When connecting the fender with a steel wire rope, the wire rope should be fitted with a rubber sleeve to avoid damage to the fender.

4.Do not touch the fender surface with the the sharp objects, to prevent piercing the fender. If the fender's surface is damaged, it will affect the lifespan of the fender.

5.When the fender is in normal use, the fixing points should be firm, prevent the detachment and wash away the fender. Suspension of the rope and hook ring should be connected orderly, can't be in a mess.

6.If the fender won't be used in a long time, to clean the fender surface with fresh water. and place the fender in a dry, cool, ventilated place, without direct sunshine.

7.When the fender is stored for a long time, the pressure should be reduced and the fender should be placed far away from the heat source.

8.Because the fender is rubber product, should try to avoid the fireworks, not contact with acid, alkali, oil and other organic solution

9.When the fender is stored, it shall not be folded or stacked, and don't stack other objects on the fender.

Production Equipment

Application of Our Pneumatic Rubber Fender